Visiting Catalano at Fabrica di Roma – Where Craft Meets Technology in Italian Design

Last week I had the pleasure to visit Italy, and team up again with Catalano. I previously wrote an article about their Tonalità collection and participation in ‘Architect at Work’ (see here) Together with a small group of friends I often travel with, we were invited to visit their factory, located at Fabrica di Roma near Viterbo. A huge complex where they create functional and sustainable design products combining craftsmanship and high technology

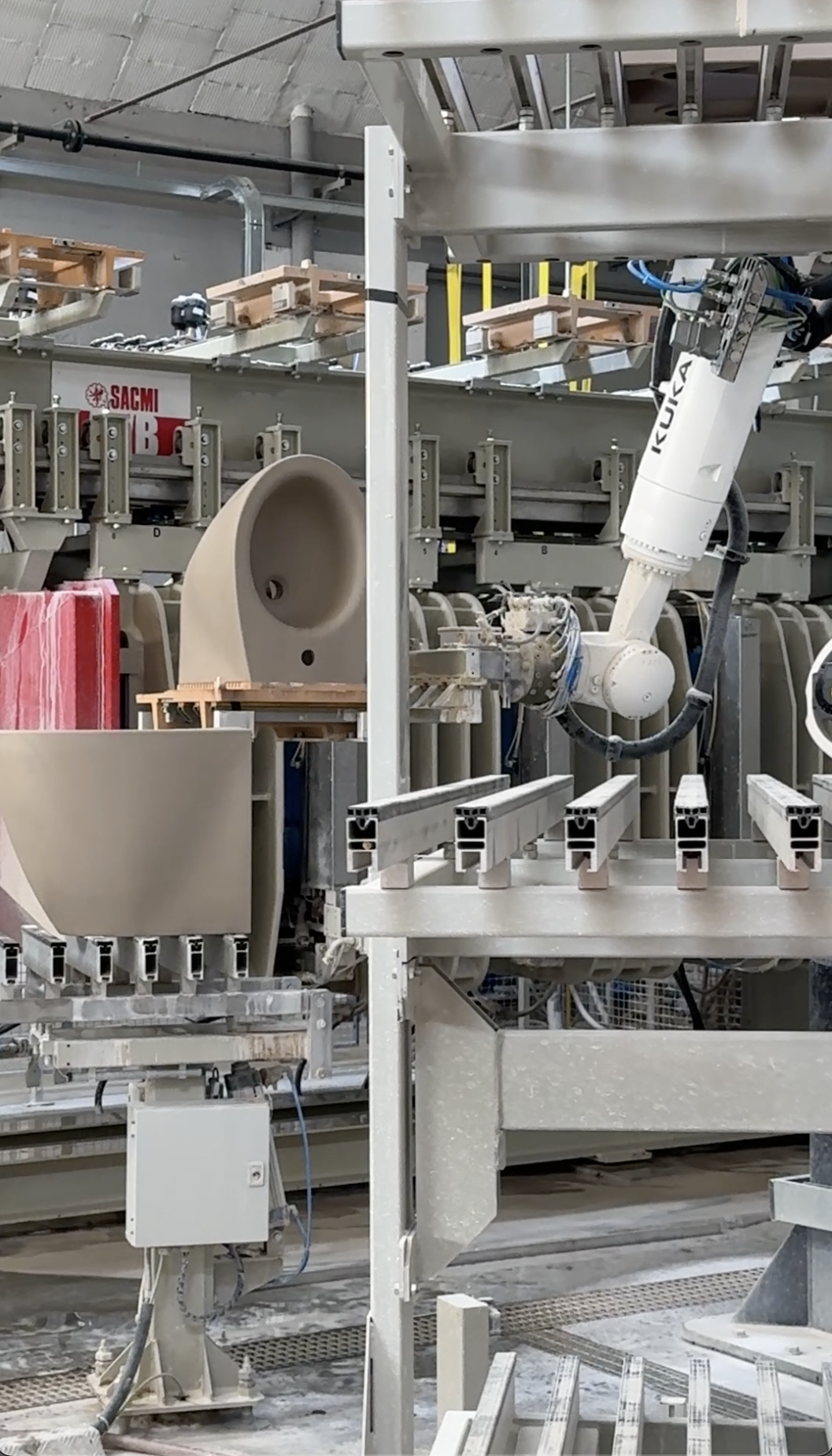

Catalano is the first company able to offer the highest productive quality in Made in Italy sanitary-ware sector. No wonder I was really impressed by the many robots in operation we saw. The company seamlessly combines advanced automation with age old craftsmanship unique to their region. all of which is reflected in a vast collection of exclusive designs of top quality.

After a short introduction we had the opportunity to get a peek behind the production of the various products. Think of wash basins, shower trays, bath tubs, sanitary ware and more. I have visited different factories over the years, but as said before, I was deeply impressed by the robots that each performed their own task in succession. Everything is literally made from earth, water and fire!

Catalano factory tour

Raffaele Ceccarelli, chief production engineer at Catalano, guided us through the different stages with great enthusiasm. From the warehouse where literally mountains of clay imported from all over the world were stored. To the lab where research is done, and the full production process by robots, craftsman and engineers. It really was a super interesting experience to see such a large company in operation.

With the production of toilets and bidets, of which the robot produces 1200 per day, we started our tour, it is impossible to show you all the small clips I made of the different stages in this blogpost, you will however find more of the process captured by me during the tour on my Instagram, see here: vosgesparis Instagram To show you the total process from soil to design product, you will also find a video at the end of this post.

A fully automatic process

Beside the high quality products made at Catalano, the fully automatic process is just amazing to watch. From high pressure casting, to how products are placed on large carts by the robots, and being automatically picked up by a transport car when full, to be moved to the dry room. A large space where by temperatures of 32-38 degrees the dry process takes place for about 24-36 hours. You could clearly see the different stages of drying and the slow change of colour from the wet dark clay colour to a lighter when almost dry.

Industrial Evolution – Linea 7

Last year Catalano introduced a new glass robot: the Linea 7. A series of robots that work in a production line and perform all glazing and finishing operations. This allows products to go from the drying room via 7 production stages directly to the kiln.

Each robot has its own task, from adding glaze on different sides to removing dust. An X-ray scanner carefully looks for cracks or defects before the piece is sent to the next stage of coating and at the end the anti-lime scale and antibacterial glaze is sprayed. After which the glazed products are sent to the kiln where they are baked at 1250 degrees for 24 hours.

The fact all operations that the robots perform took place in fully enclosed booths, not only gave us the possibility to look at the process real close up, but this approach also ensures no dust disperses into the working environment, making a safe environment for their workers.

Sustainability

Raffaele also took us to the warehouse where the raw materials are stored and here it became clear again how sustainable the company is. No waste: everything is reused from clay to waste water. The continuous collecting and analysing of data during every stage of the production process reduces waste.

For Catalano, Sustainability also means respect for the environment, and the well-being of the community in which the company operates. Social Responsibility is expressed in the many collaborations with universities and secondary schools in their ceramic region, to ensure the professional training of young people is in line with the current state of Catalano’s technology. Through workshops and training programmes interest in the ceramic industry is generated.

Research & Technologies

We finished our tour at The Lab, where Catalano has been investing for years in technological innovation and experimentation in materials science, aiming to obtain products which guarantee the highest levels of hygiene. Chemical analysis is performed on raw materials, chosen by the lab’s manager Giulia Simonetti herself from the quarries. The constant drive to innovation of Catalano laboratories and the exceptional skills of the technicians resulted in different advanced features and the best quality ceramic sanitary.

Many new innovations in the production of bathroom & sanitary ware were designed by the Catalano team, such as the different glazings that ensure the highest hygienic and easy to clean surfaces, such as Cataglaze+® and Twinglaze+®. And the Silentech® with its silent, rimless flushing technology

Cataglaze+®

Cataglaze+® offers total antibacterial protection through a unique, impermeable glazing treatment designed to last a lifetime. This advanced surface finish uses the natural antibacterial properties of silver and titanium particles, creating a high-performance glaze that actively prevents bacteria growth. The result is a hygienic, durable, and easy-to-clean surface—perfect for modern bathroom environments

Twinglaze+®

At the factory these black toilets caught my eye, they have a unique finish! The WCs are treated with Cataglaze+® glossy inside and satin outside. This gives the WC a refined, modern touch. Twinglaze+® is available on all Catalano’s coloured WCs.

Silentech®

Silentech® is the most advanced flushing system on the market, combining cutting-edge design with superior performance. Its silent, rimless flushing technology ensures maximum hygiene and easy cleaning, while the innovative vortex water flow provides powerful surface action for impeccable cleanliness. This advanced system not only reduces the need for chemical detergents but also minimizes noise and water consumption, making it a sustainable and contemporary choice for modern bathrooms. Available on 99% of Catalano toilets.

Curious to see the whole process as we got to experience during our Catalano factory tour, watch the video !

Images and video by catalano and vosgesparis

Written in collaboration with Catalano

– vosgesparis partner –

Het bericht Visiting Catalano at Fabrica di Roma – Where Craft Meets Technology in Italian Design verscheen eerst op vosgesparis.